Trustworthy Relationships of Integrity

As a globally renowned leader in communication and

entertainment electroacoustic products, Merry is committed

to promoting sustainable supply chain management, viewing

suppliers as important partners. Through stable and close

cooperation with suppliers, we aim to create economic value

while also expecting our supplier partners to jointly adhere

to the RBA Code of Conduct and emphasize social and

environmental responsibility, thereby creating a sustainable

and mutually beneficial supply chain together.

01

Announced Supplier Code of Conduct

02

100% completion on CSR audits

03

achieving 100% conflict minerals-free metals

04

97% signing rate of Social and Environmental Responsibility Commitment

Supply Chain Management

Source management

New Supplier Selection System

When MERRY selects new suppliers, an evaluation team comprising representatives from procurement, quality, R&D, and engineering departments conducts assessments. The evaluation scope encompasses not only basic company information, quality systems, and intellectual property rights as commercial indicators but also thoroughly examines suppliers’ performance in chemical restricted substances management systems, social and environmental sustainability initiatives, labor rights protection, prohibition of conflict minerals, and corporate governance within ESG dimensions. This process identifies risks specific to certain industries or product suppliers. Suppliers must undergo evaluation and receive approval to be included in the qualified supplier list.

Compliance with Sustainability

MERRY adheres to the RBA Code of Conduct requirements and has formulated the''Supplier Code of Conduct'' based on this standard. It covers regulations related to labor,health and safety, environment, business ethics, and management systems. Suppliers are required not only to comply with the Code but also to observe the laws and regulations of their operating jurisdictions. MERRY also encourages suppliers to require their upstream suppliers to adopt this Code. In 2024, MERRY established the ''Conflict Minerals Policy'' to enforce procurement responsibility. Suppliers must utilize smelters certified by the Responsible Minerals Initiative (RMI) to comply with conflict minerals regulations,uphold corporate responsibility for human rights protection, manage suppliers' due diligence programs on conflict minerals, enhance transparency of supplier information,and ensure the company complies with regulatory and customer requirements.

Signing of the Social and Environmental Responsibility Commitment

To fulfill commitments to social and environmental protection responsibilities and to enhance responsible procurement management, the ''Supplier Operational and Environmental Sustainability Commitment'' has been implemented. This document encompasses three key areas: labor conditions, ethical standards,and environmental protection. Suppliers are required to adhere to relevant social responsibilities and prioritize environmental protection, working collaboratively with MERRY to promote a green supply chain.

Note: Suppliers who have not signed the Supplier Operational and Environmental Sustainability Commitment and the Conflict-Free Metals Declaration are designated suppliers by the customer.

Conflict Minerals Investigation

MERRY declares and commits to not accepting metals sourced from conflict mineral areas. Suppliers are required to sign the ''Conflict-Free Metals Declaration'' and comply with the OECD Due Diligence Guidance.Using the latest version of the Conflict Minerals Reporting Template (CMRT), supplier material mineral origin investigations are conducted through the GPMS system.Suppliers are required annually to truthfully and comprehensively disclose whether metals used in product materials originate from certified mining areas. In 2024, complete the survey 621 Suppliers of products containing minerals such as gold (Au), tantalum (Ta),tin (Sn), and tungsten (W) must ensure 100% traceability to RMI-certified compliant metal smelters.

Supplier Auditing

Regular performance monitoring and evaluation of suppliers are conducted through an assessment system covering price, quality, delivery, and service. Performance evaluations are categorized into three levels: A, B,and C. Suppliers with unsatisfactory overall scores or whose incoming material spot checks reveal non-compliance with hazardous substance standards undergo supplier improvement and effectiveness tracking according to a guidance plan. This ensures continuous iterative improvement and a cyclical mechanism to guarantee that suppliers meet MERRY's standards.

Furthermore, MERRY annually reviews and revises its supplier CSR Audit operations based on the latest version of the RBA. Suppliers receiving an audit rating of C must undergo guided improvement prior to re-engagement;a D rating designates a supplier as non-compliant, resulting in the termination of the cooperative relationship.

As of 2024, the Group comprises 926 tier-1 suppliers. Cumulative CSR audits have been conducted on 334 suppliers (36.07%), representing 85.9% of the procurement value from manufacturing suppliers.

Key Supplier Audit

For 2024, MERRY identified 59 key suppliers for onsite/online audits, based on criteria such as procurement value and high-risk materials. Among these, 3 suppliers ( 5% ) were identified with negative social or environmental impacts requiring remediation. All (100%) successfully completed the necessary improvements and passed within 90 days, achieving a 100% post-remediation pass rate (all rated B or above), with an average score of 85.8 points. 59 Key Suppliers account for 22.6% of the group's manufacturing supplier procurement value.

Note:

1. Key Supplier Selection Criteria:

1.1Key Suppliers: Manufacturers (excluding traders and agents) with over 500 delivery batches and transaction amounts exceeding 2 million in the previous year.

1.2High-Risk Material Suppliers: Manufacturers of battery cells, PCBs,metal surface treatments, color boxes, leather goods, wires, plastic/rubber tape printing and coating, hazardous chemicals, etc.

2. Material suppliers with on-site audit scores above 80 in the previous year and whose audit non-conformities have been closed are exempt from this year’s audit.

3. Audit ratings are categorized into four levels from A to D, with scores of ≧ 90, ≧ 70, ≧ 60, and <60, respectively.

1. Key Supplier Selection Criteria:

1.1Key Suppliers: Manufacturers (excluding traders and agents) with over 500 delivery batches and transaction amounts exceeding 2 million in the previous year.

1.2High-Risk Material Suppliers: Manufacturers of battery cells, PCBs,metal surface treatments, color boxes, leather goods, wires, plastic/rubber tape printing and coating, hazardous chemicals, etc.

2. Material suppliers with on-site audit scores above 80 in the previous year and whose audit non-conformities have been closed are exempt from this year’s audit.

3. Audit ratings are categorized into four levels from A to D, with scores of ≧ 90, ≧ 70, ≧ 60, and <60, respectively.

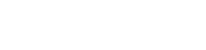

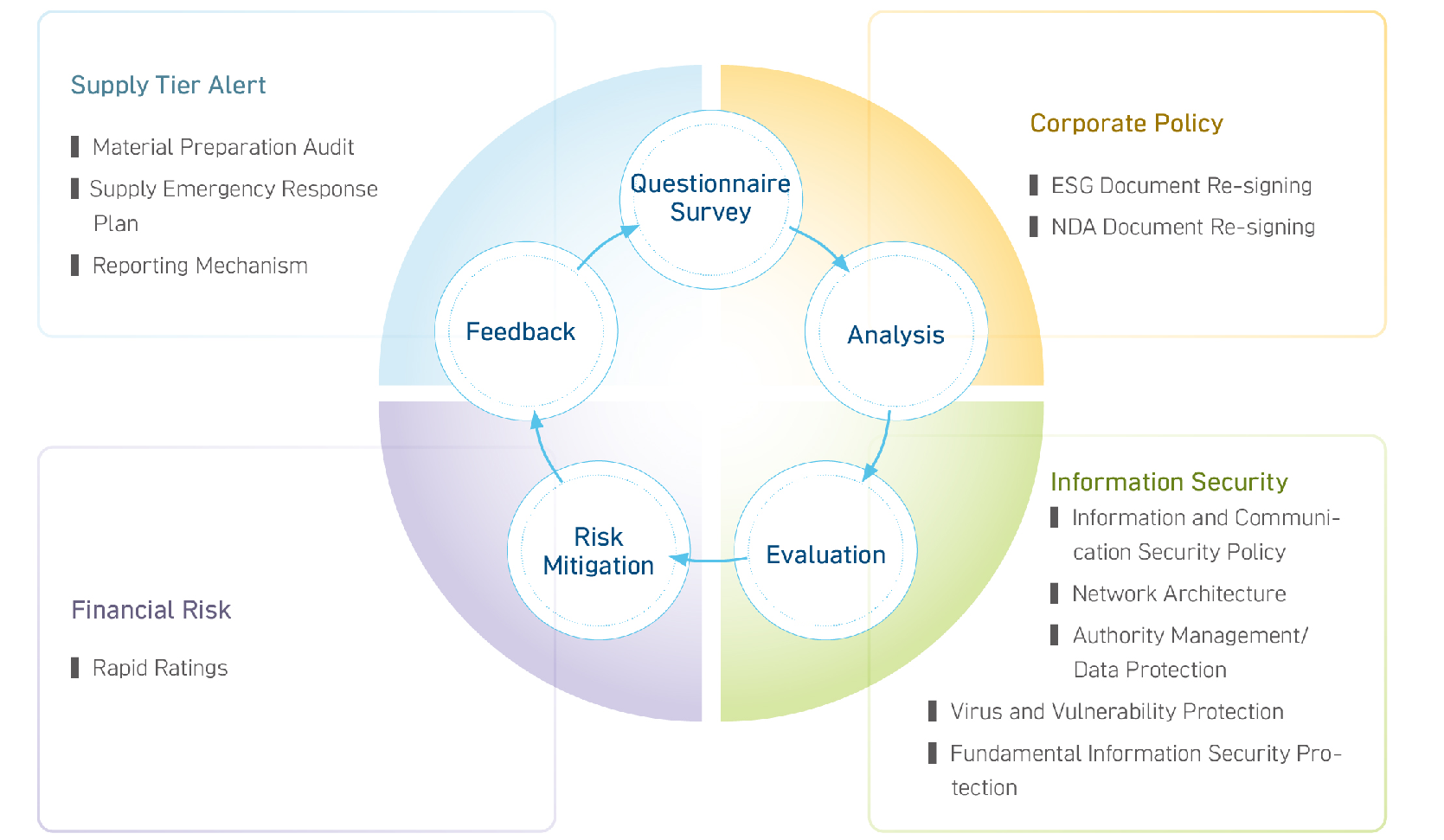

For suppliers with whom we have transactions, we assess them based on different risk evaluation methods (such as critical materials, procurement amounts, customer requirements, etc.). We regularly implement a cyclical management mechanism that includes questionnaire surveys, analysis, evaluation, risk response, and feedback to complete four risk management aspects: "Company Policy," "Financial Investigation," "Information Security," and "Supplier Classification Alerts." This ensures stable monitoring of supplier operations to reduce impacts and losses caused by climate change, pandemics, financial operational crises, and cyber intrusions.

Supplier Risk Management

Supply Grading Alert

In 2024, supply will fully meet customer demand with no abnormalities.

Financial Health Check

In 2024, the third-party financial analysis system—Rapid Ratings platform—will be adopted to perform professional analyses for supplier financial risk management. In 2024,financial health check analyses will be conducted on 180 companies (including key suppliers, potential cooperative suppliers, and original electronic material manufacturers) to classify risk levels (Very Low Risk, Low Risk, Medium Risk, High Risk, Very High Risk) and mitigate operational cooperation risks.

Information Security Assessment

Conducted by the Information security promotion team in accordance with ISO 27001 standards, establishing five key dimensions (Information Security Policy, Network Architecture,

Authority Management/Data Protection, Virus and Vulnerability Protection, and Fundamental Cybersecurity Measures) as assessment criteria. This includes a comprehensive evaluation of industry cybersecurity risks and supply chain disruption risks, effectively identifying and preventing information security incidents originating from suppliers, thereby mitigating the capacity risk impact assumed by MERRY. In 2024, a tiered evaluation (Grades A, B, C) was conducted on 26 Key Suppliers regarding risks associated with access to organizational assets; no anomalies were identified.

Authority Management/Data Protection, Virus and Vulnerability Protection, and Fundamental Cybersecurity Measures) as assessment criteria. This includes a comprehensive evaluation of industry cybersecurity risks and supply chain disruption risks, effectively identifying and preventing information security incidents originating from suppliers, thereby mitigating the capacity risk impact assumed by MERRY. In 2024, a tiered evaluation (Grades A, B, C) was conducted on 26 Key Suppliers regarding risks associated with access to organizational assets; no anomalies were identified.

Localization

MERRY continuously develops and enhances local procurement and supply chain diversification to improve allocation flexibility. To accelerate material flow, enhance communication efficiency, and reduce carbon emissions during transportation, a localized procurement strategy is implemented based on the location of production facilities,prioritizing local suppliers and assisting them in improving supply quality to strengthen their core competencies. Furthermore,continuous monitoring is maintained regarding whether suppliers’ locations may be impacted by climate change or unforeseen natural disasters affecting production or transportation, ensuring stable supply allocation through short supply chains and localized services.

In response to the impact of geopolitical challenges on the supply chain, MERRY, in 2024 and in conjunction with its risk diversification strategy, has production support and allocation not only from the China Plant but also from facilities in Thailand and Vietnam. The China Plant's local procurement amount ratio is 48%, with non-electronic components accounting for 98%. For non-China Plants, the local procurement amount ratio is approximately 8%, with non-electronic components at 16% (primarily, electronic materials are procured by customers from well-known major manufacturers, such as semiconductor components).

Communication and Development

During the product project development phase,MERRY's R&D unit, procurement unit, customers, and suppliers collaborate to discuss issues and share technologies,resolving bottlenecks at each stage and assisting suppliers in process and quality optimization.

Furthermore, to collaboratively advance sustainability initiatives,we strengthen connections and interactions with supplier partners through strategic supplier meetings, the Green Academy, and the SCM supplier information exchange platform. This facilitates bidirectional communication and dialogue with supplier partners, enhancing mutual cooperation, tacit understanding, and consensus, thereby continuously progressing towards sustainable development.

Green Academy

Since 2022, MERRY has continuously implemented supplier development and training. In 2024, three online Green Academy sessions were conducted for first-tier material manufacturers, with a total of 296 suppliers participating.Through courses covering green product specifications,international ESG development trends, and environmental regulations, ESG management concepts are promoted and advocated to key suppliers, thereby advancing MERRY’s sustainability strategy and policies related to green supply chain management.

Key Green Supply Chain Success Cases

In recent years, topics such as carbon reduction and green environmental protection have garnered significant attention.MERRY actively collaborates with core suppliers to jointly advance a greener planet. For instance, it partners with Dongpu Group, a supplier of plastic molds and injection molding, to co-develop green materials including recycled resin and water-based paint processes, thereby enhancing the sustainability characteristics of end customers’products. Furthermore, five additional suppliers are executing carbon emission optimization through equipment upgrades (e.g., conversion from hydraulic to electric systems),energy renewal initiatives (e.g., solar photovoltaic power installations), or the adoption of environmentally friendly materials (e.g., biodegradable and recyclable CCL materials).