Trustworthy Relationships of Integrity

As a globally renowned leader in communication and

entertainment electroacoustic products, Merry is committed

to promoting sustainable supply chain management, viewing

suppliers as important partners. Through stable and close

cooperation with suppliers, we aim to create economic value

while also expecting our supplier partners to jointly adhere

to the RBA Code of Conduct and emphasize social and

environmental responsibility, thereby creating a sustainable

and mutually beneficial supply chain together.

01

Announced Supplier Code of Conduct

02

100% completion on CSR audits

03

achieving 100% conflict minerals-free metals

04

97% signing rate of Social and Environmental Responsibility Commitment

Quality & Service

Customer Rights Protection Policy

MERRY primarily serves international brand clients. Although it does not directly engage with end consumers, it fully acknowledges that product quality and safety ultimately affect the brand customers’market reputation and the end consumers’experience. Therefore, MERRY has established comprehensive policies to protect Customer rights, ensuring that every phase—from product design and raw material selection to manufacturing processes and after-sales service—safeguards Customer interests and indirectly upholds the health and safety of the End Consumer.

Customer Satisfaction

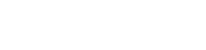

In addition to proactively conducting an annual satisfaction survey before the first quarter each year, MERRY also employs a scorecard mechanism (Score Card) for supplier evaluation by customers to assess their feedback, opinions, and requirements regarding MERRY. Relevant information is consolidated and analyzed to identify root causes, propose improvement plans, and actively promote implementation and subsequent follow-up on outcomes.

The satisfaction survey and scorecard mechanism cover four key dimensions: Quality,Research and Development, Procurement, and Integration. These serve as essential reference indicators for improving subsequent related operations and business activities. After consolidating various issues, they are forwarded to the responsible units for root cause analysis and the submission of improvement plans within a specified timeframe. In addition to responding to the customer, the matters are also assigned to the audit and marketing departments for subsequent follow-up and improvement. The comprehensive satisfaction score for major Customers in 2024 (accounting for 66% of revenue) is 87.73 points,an increase from 83.21 points in 2023.

Digital Optimization

All industries face the challenge of accelerating the speed of information delivery to customers. Enterprises must respond to this highly dynamic era by expediting comprehensive digital transformation. Since 2021, MERRY has embarked on digital transformation by implementing innovative approaches such as process robotics and global supply chain digital management in production management,while also enhancing customer relationship management through digital optimization. MERRY maintains a high customer concentration; therefore, based on revenue share and transaction frequency, it has implemented bidirectional electronic data interchange with customers to optimize service processes.

Quality Management System

MERRY has achieved ISO 9001:2015 Quality Management System certification, establishing a systematic product development process to ensure that new products meet customer requirements regarding quality, cost, and delivery time, while continuously optimizing to enhance product competitiveness. The quality assurance system involves cross-departmental collaboration among Research and Development, Quality Management, Sales, manufacturing sites, and supply chain management, and optimizes quality management and customer service through a cyclical process of planning, implementation, inspection, and improvement.

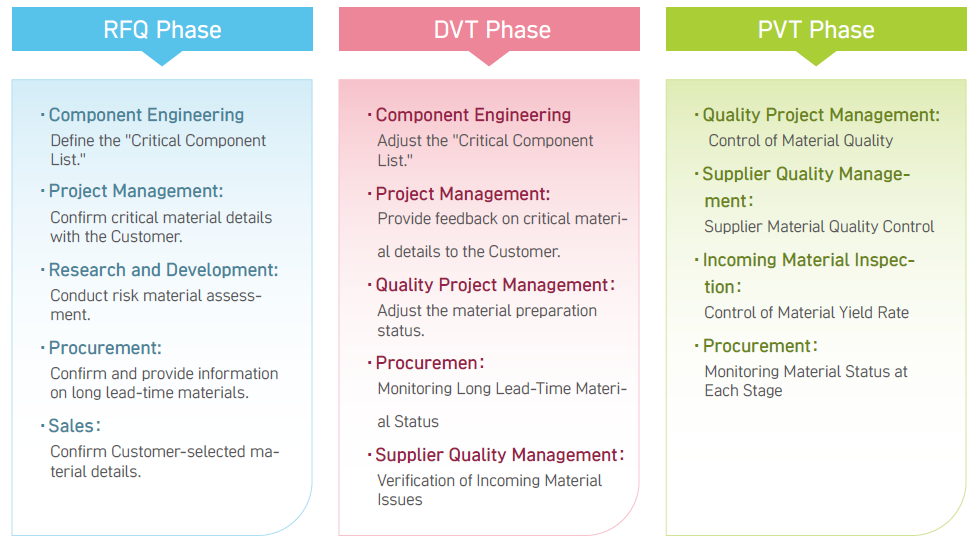

Critical Material Management Process

To enhance new project development efficiency and customer satisfaction, MERRY has established the "Critical Material Definition and Operational Procedures" to identify and control key components affecting production quality,ensuring quality, delivery schedule management, and mass production quality at every stage.