Trustworthy Relationships of Integrity

As a globally renowned leader in communication and

entertainment electroacoustic products, Merry is committed

to promoting sustainable supply chain management, viewing

suppliers as important partners. Through stable and close

cooperation with suppliers, we aim to create economic value

while also expecting our supplier partners to jointly adhere

to the RBA Code of Conduct and emphasize social and

environmental responsibility, thereby creating a sustainable

and mutually beneficial supply chain together.

01

Announced Supplier Code of Conduct

02

100% completion on CSR audits

03

achieving 100% conflict minerals-free metals

04

97% signing rate of Social and Environmental Responsibility Commitment

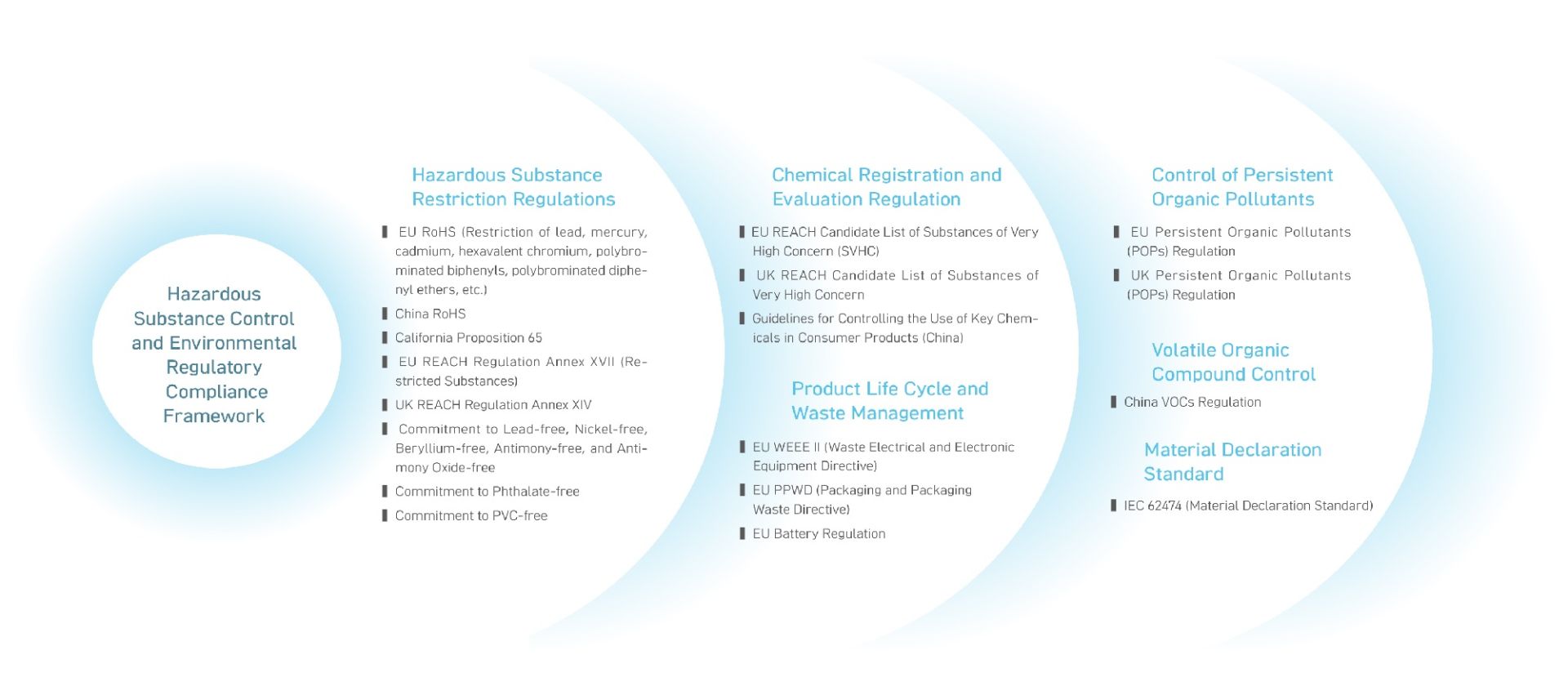

Green Product Management

Environmental Substance Control Management

(Hazardous Substance Management) Process

__25I04YMhTK.png)

Hazardous Materials Inspection

Ensure the health of end users and

reduce the potential environmental impact of products.

reduce the potential environmental impact of products.

GC-MS

Inspection of Plastic and Non-Metal Materials

XRF

Inspection of Metal Materials

FTIR

Material Analysis for Customer Complaint Products and Uncertain Materials

Green Product Management System

Reusability and Recycling Rate

55%

YEAR 2024

Recycling Rate of Recycled Materials

75%

YEAR 2024

Products comply with international environmental regulations

100%

YEAR 2024

MERRY has established a comprehensive Green Product Management System (GPMS), mandating that suppliers strictly adhere to the ''Environmental Substance Control Management Measures''. All suppliers are required to upload complete green component approval documentation,including the ''Green Declaration'', ''Material Certificate'',and ''Relevant Test Reports''. Through a systematic audit process, MERRY ensures that all components comply with international environmental regulations, directives, and customer requirements. In 2024, 100% of MERRY’s products will comply with international environmental regulations.

Supplier Management: Require all suppliers to fully understand and comply with international regulations concerning hazardous substances. Specifically, with regard to Substances of Very High Concern (SVHC) under the REACH regulation, suppliers must conduct comprehensive investigations and controls to ensure product safety.

Incoming Material Inspection System: Implement a rigorous incoming material inspection system, utilizing batch sampling principles for random testing. We employ various advanced analytical instruments to ensure raw materials are free from hazardous substances, including X-ray Fluorescence (XRF) analyzers for metallic materials, Gas Chromatography-Mass Spectrometry (GC-MS) for plastics and non-metallic materials, and Fourier Transform Infrared Spectroscopy (FTIR) for material analysis of customer complaint items and unidentified materials. measures.Any raw materials found to violate controlled substance regulations shall be classified as non-conforming products,requiring the Supplier to immediately submit supporting documentation. If ultimately confirmed as non-conforming products, they shall be processed through return, and the Supplier must implement corrective and preventive actions to prevent recurrence.

Product Labeling and Regulatory Compliance: MERRY’s entire product line strictly adheres 100% to the labeling specifications established by brand customers.Relevant certifications required by product attributes are confirmed during the design phase for packaging labeling to comply with product labeling regulations across different regions. In 2024, no incidents of regulatory violations or customer claims due to labeling issues have occurred. No incidents of violations related to health and safety regulations concerning products and services, nor any complaints regarding product health and safety, occurred in 2024.。

Supplier Communication and Education: In 2024, two supplier conferences were held: one promoting MERRY's CSR, RBA, and GP-related regulations, organizational carbon inventory, and ESG trend topics; the other focused on promoting EU regulatory requirements.

Product Recycling and Circular Utilization: In accordance with product structure principles and the requirements of the WEEE directive, products are entrusted to certified laboratories for disassembly. MERRY primarily manufactures products for brand clients on an OEM basis.In 2024, all manufactured products achieved a reuse and reutilization rate of 55% and a recycling rate of 75%. However,final waste recycling is carried out by the end brand clients.