Occupational Safety and Health Management System

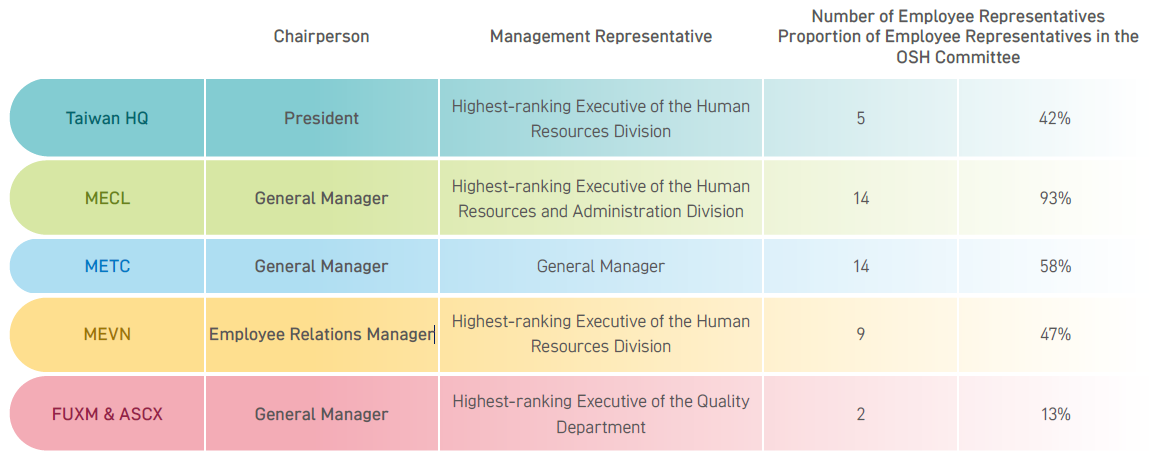

MERRY upholds its occupational safety and health policy of ''protecting employees, promoting health, preventing hazards, and reducing occupational injuries''. In accordance with occupational safety and health regulations, it promotes an occupational safety and health management system, establishes OSH principles, objectives, and indicators, and conducts regular execution and inspections to comply with OSH laws and relevant requirements.This is to provide a safe and healthy working environment, eliminate hazards, reduce OSH risks, and promote OSH consultation and participation, thereby ensuring that internal operations consistently meet safety and health policies and regulations.The Taiwan headquarters, MERRY Shenzhen, MERRY Vietnam, and OSD hold quarterly "Occupational Safety and Health Committees," inviting labor representatives to discuss and implement the spirit of worker participation. The following table provides information on the chairpersons, management representatives, and labor representatives at each operational location.

To ensure the effective operation of the occupational safety and health management system,operational sites certified to ISO45001:2018 regularly convene the Occupational Safety and Health Committee (hereinafter referred to as the OSH Committee). Employee representatives are invited to participate in discussions to embody the spirit of worker participation.

In addition to carrying out relevant matters for continuous improvement based on the items listed on the right, the table below presents the proportion of management personnel serving as chairpersons and the ratio of employee representatives for each operational site:

Rights of Employee Representatives in the Occupational Safety and Health Committee

1. Respond to employee feedback (including OSH resource requirements and risk control requirements)

2. Participate in the development and review of OSH policies, objectives,and procedures

3. Dissemination and communication of meeting resolutions

4. Participate in incident investigation activities.

5. Provide recommendations on significant occupational safety and health matters or issues.

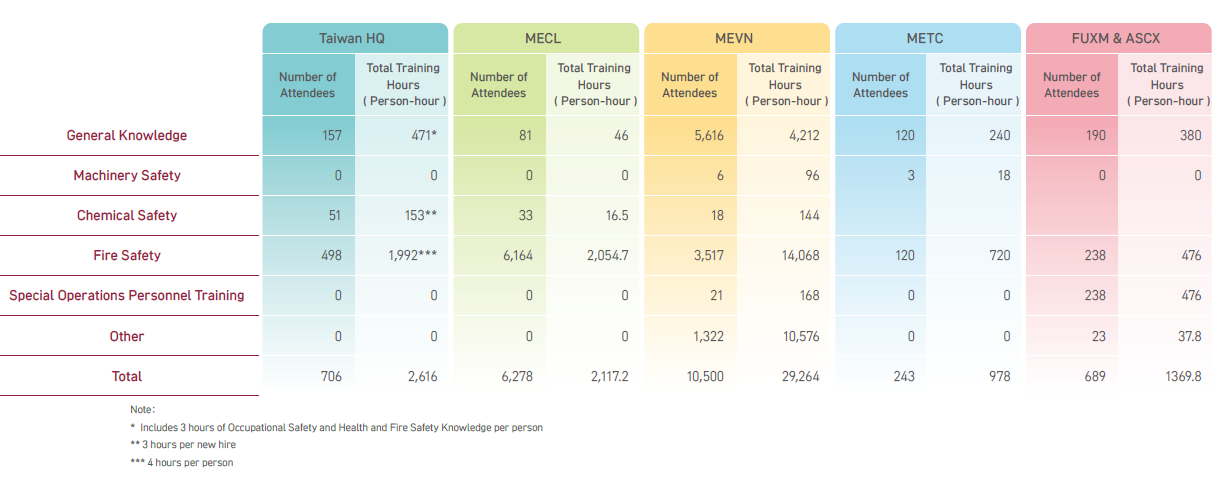

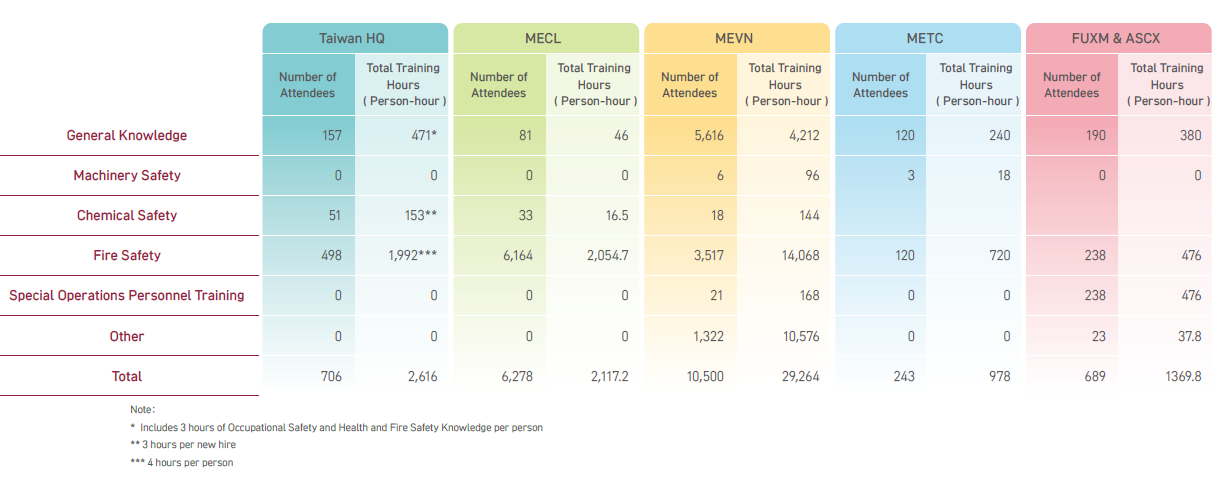

Sites certified to ISO 45001:2018 include Taiwan Headquarters, MECL, MEVN, FUXM and ASCX, and METC (certification anticipated in 2025 ). These sites undergo regular audits and verification by third-party organizations. The scope encompasses employees and non-employees involved in work activities such as design, development, procurement, construction, production, maintenance, and contracting. While MSCS possesses an occupational safety and health management mechanism, it does not yet fully conform to the ISO 45001 management framework. Future plans involve the phased implementation of the occupational safety and health management system at operational sites with production activities year by year, aiming to achieve external certification. Due to the varying style of each site,MECA, MESG, MEST, MENA, and MEMP are classified as R&D and sales offices with a limited number of personnel, thus presenting a lower risk of disabling injuries. Therefore,appropriate management methods have been established in accordance with local regulations. Currently, these sites are not yet included within the ISO 45001 certification scope.MERRY’s personnel engaged in high-risk operations complete relevant safety training and retraining in accordance with local regulations. Training hours and categories are presented in the table.

Hazard Identification, Risk Assessment, and Incident Investigation

The Site/Facility validates the collection of significant negative occupational safety and health impact events directly related to the company's operations, products, or services. Simultaneously, it identifies and records potential safety and health hazard factors (including physical, ergonomic, chemical, biological, and psychosocial aspects) inherent in various operational activities and facilities. This process aims to assess high-risk workers and implement risk reduction management measures, striving for zero accidents.

To proactively prevent or subsequently mitigate potential environmental impacts and hazards before and after the occurrence of emergencies, the ''Major Disaster Emergency Preparedness and Response Measures Management Procedure'' has been established.This procedure is applied in daily operations to prevent incidents that could cause environmental and safety impacts and hazards. For instance, to prevent fires and ensure timely rescue and extinguishment, practical firefighting lectures and actual drills with firefighting equipment are arranged annually, enabling all personnel to acquire enhanced firefighting knowledge and skills. MECL conducts monthly in-house fire brigade drills, holds daily pre-shift safety briefings, and commissions a third-party organization to perform monthly maintenance on factory firefighting facilities to ensure daily factory fire safety. Should life-threatening situations arise during work (e.g., earthquakes, fires, explosions, toxic substance leaks, etc.), employees are to proactively avoid the danger, evacuate the hazardous area, and immediately inform their direct supervisor, without fear of any punitive action.

Should workers identify any non-compliant operational practices, new potential risks, or issues, the designated occupational safety and health specialist, in accordance with the ''Health Management Procedures'' and ''Accident Investigation and Handling Procedures'',shall be responsible for tracking and implementing improvements, initiating investigations into the root or potential causes of incidents, and evaluating revisions to relevant regulations and preventive measures to ensure a safe and healthy working environment. Employees may also report safety and health-related issues and suggestions, which will be evaluated by the occupational safety and health department. Furthermore, for employees who file complaints through company channels, to ensure the protection of the complainant,the handling, employee feedback, and subsequent follow-up will be conducted confidentially.

The 2024 risk assessment and control results verify that all sites have completed hazard identification and risk assessment.

Occupational Safety Training and Education

MERRY regularly arranges occupational health and safety-related training and education to ensure that every employee is familiar with relevant regulations and the company's safety and health management mechanisms, thereby enhancing overall safety awareness.

In addition to new hires receiving general safety and health education and training (including occupational safety and health and fire safety knowledge), regular training courses on hazardous chemicals, fire safety, and other related subjects are arranged for existing employees to enhance their safety awareness and practices. Personnel involved in occupational safety and health are required to undergo periodic retraining as per legal mandates, reinforcing the provision of employee safety and health education and training to elevate the safety consciousness of all staff. MECL periodically organizes public safety training courses and seminars.Concurrently, MEVN provides safety training for all newly onboarded personnel and annually engages external partners to conduct labor safety training. Both MECL and MEVN 's production line machinery is equipped with clear operating procedures, specifications, and maintenance records,with integrated safety mechanisms and measures designed to protect employees from occupational injuries.FUXM and ASCX also regularly provide training related to Safety and Health.

MERRY's high-risk operational personnel complete relevant safety training in accordance with regional regulations.Training hours and categories are detailed in the table below.Upon onboarding, all new employees must complete safety and health-related course training. All employees can also access work-related regulations and procedures at any time via the employee website to stay informed of relevant work safety regulations.